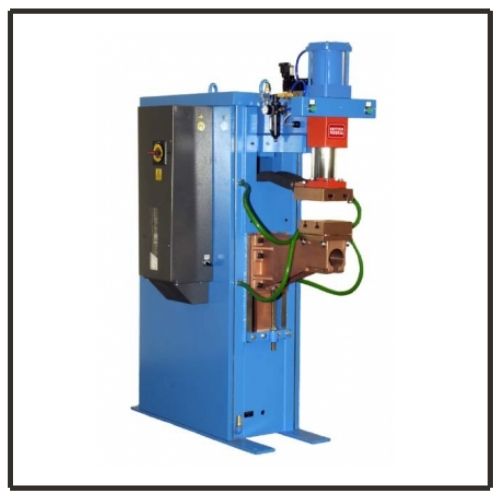

British Federal – Stronghold Projection Welder – 75 Stronghold / 100 Stronghold / 150 Stronghold

Price on Request

NOT THE RIGHT PART? YOU CAN SEE THE FULL RANGE IN OUR CATALOGUE

View Now

Stronghold projection welding machines are designed for light to medium duty applications. Built to British Federal’s high-quality standards, they are available as dedicated projection welders, complete with custom built tooling or as conversions from the Stronghold spot welder. Standard Features for projection welding include -

> EASY TOOLING ALIGNMENT - Spherical seating for the lower platen.

> TOOLING VERSATILITY - Fully adjustable platen gap.

> RELIABILITY - 50% duty cycle encapsulated transformer.

> HIGH QUALITY WELDING - Choice of weld control and AC or MFDC versions.

Stronghold can be fitted with a range of AC Weld Transformers (100 to 150kVA) or MFDC Transformers (100 to 250kVA) as well as a choice of Weld Controls and other options.

MFDC offers the following added benefits -

> Improved weld quality.

> Reduced Power consumption costs.

> Lower peak currents providing increased electrode life.

> 3-phase even load distribution.

> Ideal for welding coated materials and Aluminium.

> Weld times reduced through increased rate of heat input to work piece.

> Reduced weld splash owing to lower peak currents.

> Can be retrofitted to existing machines.

Optional extras:

> Retract/high lift and or 160mm air cylinder.

> 100KVA , 150KVA single phase AC or 100KVA 3-phase DC Medium Frequency Transformer.

> Load Cell for Force verification

> Nut Verification System

> Water Flow Sensors

> Electro-pneumatic regulator for automatic adjustment of weld force with weld program selection. (Compatible weld control required).

> Bespoke designed tooling

> Linear Transducer for Head Travel position

> Closed circuit water cooled system.

> Integration of automatic nut and bolt feed machines.

| Technical Specifications | 75 Stronghold | 100 Stronghold | 150 Stronghold | ||

| Continous power @ 100% duty cycle | Sp | KVA | 53 | 70 | 106 |

| Max short circuit power | Scc | KVA | 300 | 330 | 580 |

| Max welding power | Smax | KVA | 240 | 350 | 460 |

| Nominal power @ 50% Duty Cycle | S50 | KVA | 75 | 100 | 150 |

| Nominal supply voltage | U1n | V | 415 | 415 | 415 |

| Continous primary current at 100% duty cycle | I1p | A | 125 | 170 | 250 |

| Supply Frequency | Hz | 50 | 50 | 50 | |

| Supply phases | 2 | 2 | 2 | ||

| Supply capacity | KVA | 180 | 200 | 350 | |

| HRC fuse size to BS88 | A | 160 | 200 | 315 | |

| Feed cable c.s.a up to 30m long | mm² | 50 | 70 | 150 | |

| Max short circuit primary current | I1cc | A | 730 | 800 | 1,400 |

| Max short circuit secondary current | I2cc | A | 34,000 | 37,000 | 46,000 |

| Max welding current | I2 max | A | 27,000 | 29,000 | 36,000 |

| Duty cycle for max welding | Xmax | % | 4.8 | 7.1 | 5.2 |

| Continous secondary current at 100% duty cycle | I2p | A | 6,000 | 7,299 | 8,900 |

| Number of taps | 3 | 3 | 3 | ||

| Secondary open circuit volts | U20 | V | 8.8 | 9.9 | 11.9 |

| Weld cylinder diameter | mm | 125 | 125 | 160 | |

| Weld force min/max with a 1.5/5.5 bar supply | kN | 1.8/6.7 | 1.8/6.7 | 3.0/11.0 | |

| Weld force min/max with a 20/80 psi supply | Ibf | 400/1,500 | 400/1,500 | 650/2,500 | |

| Weld cylinder stroke max | mm | 76 | 76 | 76 | |

| Air pressure normal | bar | 5.5 | 5.5 | 5.5 | |

| Air pressure max operating | bar | 7 | 7 | 7 | |

| Air Connection/hose size | BSP/in | 1/2″/3/8″ | 1/2″/3/4″ | 1/2″/3/8″ | |

| mm | 12/10 | 12/10 | 12/10 | ||

| Cooling water min operating pressure | bar | 3 | 3 | 3 | |

| Cooling water consumption | lit/min | 20 | 20 | 20 | |

| Cooling water max inlet temp | °C | 30 | 30 | 30 | |

| Cooling water connection/hose size | BSP/in | 1/2″/3/4″ | 1/2″/3/4″ | 1/2″/3/4″ | |

| mm | 12/19 | 12/19 | 12/19 | ||

| Shipping specification | machine weight | kg | 570 | 570 | 630 |

| machine size | mm | 590W x 1,285D x 1,685H | 590W x 1,285D x 1,685H | 590W x 1,285D x 1,685H |

All of our machines are priced and sold as ‘Machine Only’ if you wish to have us deliver, Install and/or commission your new purchase, please request prices from our Sales Team. We offer a full range of services to suit all sizes of business and budgets.