News & Projects

Flexible Station Welding

Three Multi-Head Twin Station Special Purpose Projection Welders were designed for welding M5, M6 and M8 Weld Nuts and M6 & M8 Weld Bolts to pressings. The twin station concept allows simultaneous operator loading and machine welding. Efficiencies are further...

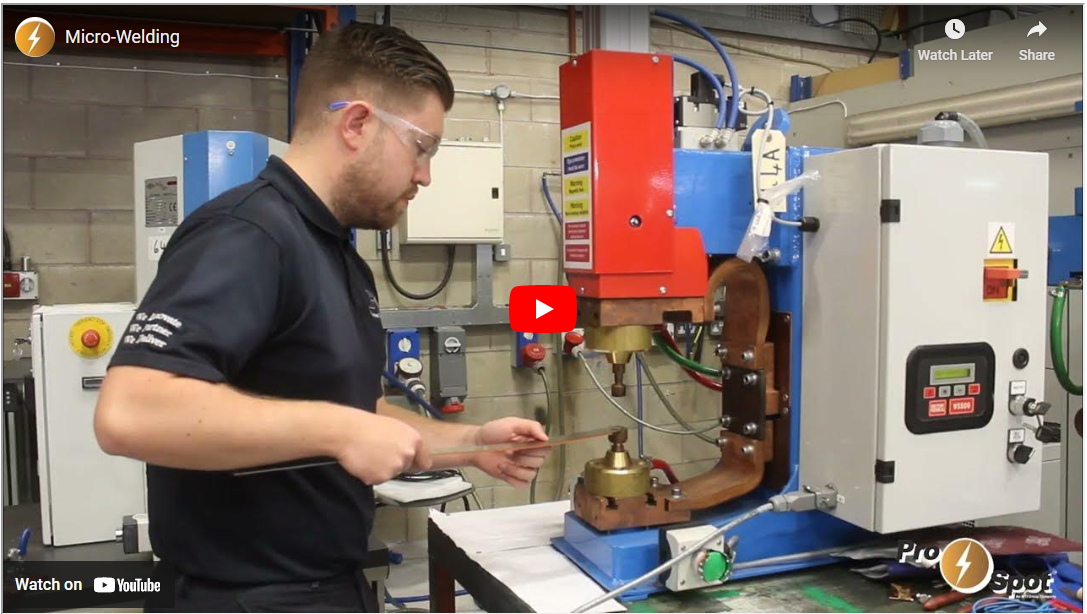

Micro-Welding

What is “Micro-Welding”? At Prospot, our micro-welding range covers equipment from 500VA (0.5kVA) to 10kVA and is generally used for the welding of small precision components in a range of ferrous and non-ferrous materials. For example, our PW500 portable spot weld...

Patch Seam Welders

The Exhaust Boxes encompass the full range of Petrol and Diesel Internal Combustion Engine vehicles as well as a novel hybrid system which uses a Petrol Engine to charge the battery with only a high output electric motor connected to the wheels. Our seam welders are...

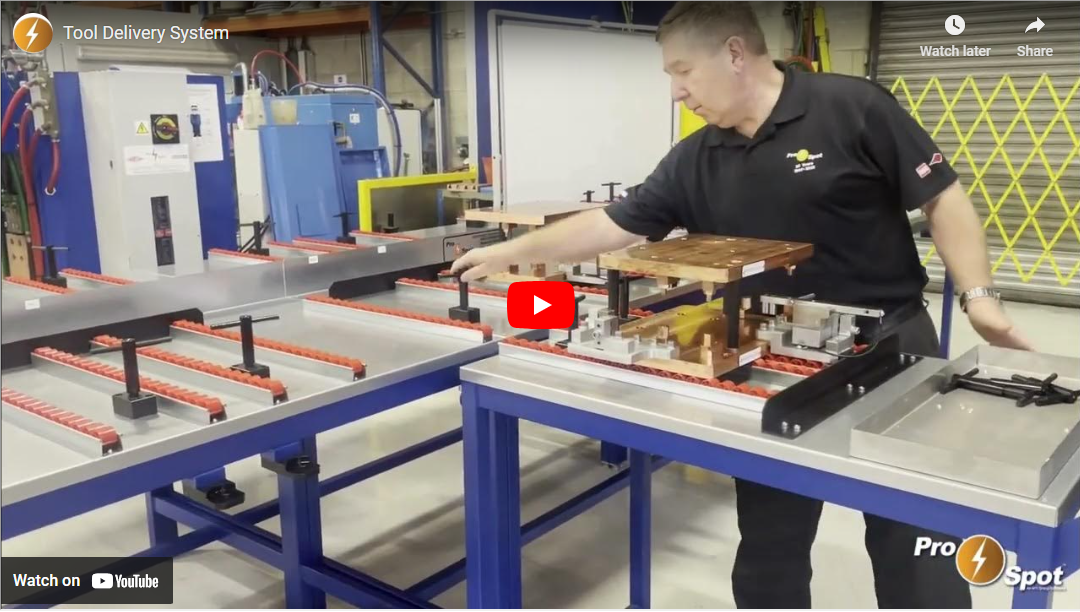

Tool Delivery System

Our Customers ask us for process solutions around the Welder. This in house designed tooling delivery system provides access to multiple tooling options, providing easy identification, eliminating the need for heavy load hoists, thus increasing process efficiency....

Tri-Robot Cell

Maximising the use of robots helps to bring the full welding process into a cell. Here 3 ABB robots are kitted out with a Ivostud Servo Controlled Short Cycle Stud Weld Gun with Auto Feed of the Weld Studs, a Serra Pneumatic AC Spot Welding gun controlled from a...