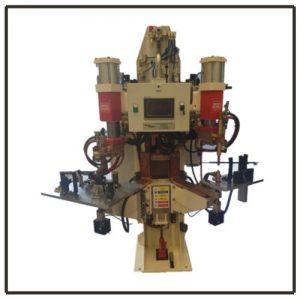

CEA – PPN Linear Spot And Projection Welders – PPN63 / PPN83 / PPN103 / PPN153 / PPN253

Price on Request

NOT THE RIGHT PART? YOU CAN SEE THE FULL RANGE IN OUR CATALOGUE

View Now

Vertical Stroke Spot And Projection Welders:

Being suitable for both spot and projection welding jobs, PPN models fully satisfy an extremely large variety of the heaviest mass production industrial applications. Equipped with a microprocessor control and safety concomitant side buttons, upon request they can also be supplied fitted with special controls and in different configurations

- Excellent Welding on all weldable metals

- Synchronous ignition SCR group with phase shift welding current adjustment to eliminate initial transient

- Thermostatic protection on the SCR group

- High welding currents with low consumption

- Set up time reduction thanks to quick and easy modifications to electrodeholders platens opening without any intervention on the secondary circuit (patent pending)

- Self-lubricated pneumatic compliments to eliminate oil deposits and to safeguard the environment from contaminants

- Water cooled secondary circuit, i.e. electrodes, electrodeholders, platens and transformer, to avoid overheating

- Water cooled copper electrodeholders with adjustable height

- Electrode force adjustable by pressure reducer group equipped with a monometer and filter for automatic air impurity expulsion

- Upper electrode movement by self-lubricated double effect pneumatic cylinder fitted with speed regulator, end stroke shock-absorber and silencer for compressed air discharge

- Solenoid valve to control welding cylinder

- Safety cycle start by means of concomitant side buttons or, alternatively only if the operator can work in safe conditions, by electric pedal. Either option can be chosen by a selector with removable key

- Cycle stop emergency button

PPN 63

THEY ARE EQUIPPED WITH:

- Lower round arm with adjustable height and lateral adjustment

- Electrodeholders with electrodes for spotwelding and ability to easily fit barholders for projection welding

- Lower arm holder can be adjusted for use with larger arm gap

- Spotwelding

- Projection welding with bars for mesh

UPON REQUEST ALSO AVAILABLE WITH:

- Different length arms (optional)

- Lower arms with pressed-in electrode (for entering pipes or boxes) and longer electrodeholders on the upper arm (optional)

- Special version with platens only for projection welding (PPN 63)

PPN 83 - 103 - 153 - 253

All supplied with lowe platen adjustable in height and fitted with T-slots, enabling the quick assembly of barholders, electrodeholders or any dedicated tooling for a specific application. Platens gap is easily and quickly adjustable without any intervention on the secondary circuit (Patent pending.)

Manual valve for upper head descent without pressure for cleaning, centering and ordinary maintenance of the electrodes

Upper head low friction driving system for precision welding (except PPN 83)

- WS 708 Electronic Control

- 8 Programs

- Half period welding time

- Pre-heating current

- Two 24 v DC solenoid valves

- 50/60 Hz frequency

- Mains voltage compensation

- Error message

- Weld/no weld switch

- Single or multi spot

| Functions | WS 708 | WS 3000 AC | FILIUS MULTI | |||

| Pre-squeeze time | . | . | ||||

| Squeeze time | . | . | . | |||

| Preheating time | . | . | . | |||

| Preheating current | . | . | . | |||

| Cooling time | . | . | . | |||

| Slope up | . | . | . | |||

| Welding time | . | . | . | |||

| Welding current | . | . | . | |||

| 1/2 Period welding time | . | . | . | |||

| Welding time 2 (2 pedal version) | . | . | . | |||

| Welding current 2 (2 pedal version) | . | . | . | |||

| Pulse interval time | . | . | . | |||

| Pulse number | . | . | . | |||

| Post heating time | . | . | ||||

| Post heating current | . | . | ||||

| Holding time | . | . | . | |||

| Pause time | . | . | . | |||

| Auto-repeat | . | . | . | |||

| Program No. | 8 | 100 | 32 | |||

| Welding current display | . | . | ||||

| Limit monitoring | . | . | ||||

| Constant current | . | |||||

| Mains voltage compensation | . | . | . | |||

| Error message | . | . | . | |||

| Spot counter | . | . | ||||

| Pressure contact | . | . | . | |||

| Cycle end contact | . | . | . | |||

| PPN 63 / PPN 83 – 103 – 153 – 253 | PPN | 63 | 83 | 103 | 153 | |

| Image | A | mm | 435 | 400 | 400 | 400 |

| A (Optional) MIN/MAX | mm | 650 | 650 | 650 | 650 | |

| B | mm | 750 | — | — | — | |

| C MIN/MAX | mm | — | 445 | 445 | 445 | |

| D MIN/MAX | mm | 180 | 145 | 145 | 145 | |

| mm | 510 | 300 | 300 | 300 | ||

| 615 | 800 | 800 | 800 | |||

| 955 | 955 | 955 | 955 | |||

| Dia mm | 60 | — | — | — | ||

| Dia mm | 35 | 30 | 35 | 35 | ||

| Dia mm | 19 | 19 | 25 | 25 | ||

| E mm | — | 150 | 180 | 180 | ||

| F mm | — | 150 | 180 | 180 | ||

| G mm | — | 63 | 63 | 63 | ||

| T | — | 2 | 3 | 3 | ||

| Technical Data | PPN | 63 | 83 | 103 | 153 | 253 |

| Single phase input 50/60 Hz | V | 400 | 400 | 400 | 400 | 400 |

| Rated power at 50% | kVA | 60 | 80 | 100 | 150 | 250 |

| Short circuit power | kVA | 142 | 266 | 366 | 575 | 763 |

| Max. welding power | kVA | 113 | 210 | 293 | 460 | 610 |

| Installed power | kVA | 38 | 65 | 78 | 120 | 195 |

| Cross section connecting cables | mm² | 35 | 50 | 50 | 95 | 120 |

| Delayed fuse | A | 100 | 150 | 200 | 300 | 500 |

| Open circuit voltage | V | 5.9 | 8.3 | 9.4 | 11.5 | 12.5 |

| Short circuit current | kA | 24 | 32 | 39 | 50 | 61 |

| Max. welding current | kA | 19 | 25 | 31.2 | 40 | 49 |

| Thermal secondary current at 100% | kA | 7.2 | 6.8 | 7.5 | 10.1 | 14.2 |

| Work stroke | mm | 65 | 100 | 100 | 100 | 100 |

| Max. electrode force (6 bar) | daN | 470 | 736 | 900 | 1200 | 1884 |

| Water consumption at 300 kPa (3 bar) | l/min | 7 | 8 | 80 | 8 | 8 |

| &mm | 1070 | 1115 | 1115 | 1170 | 1210 | |

| Dimensions | “mm | 430 | 400 | 400 | 400 | 460 |

| #mm | 1520 | 1650 | 1650 | 1800 | 1800 | |

| Weight | kg | 335 | 560 | 580 | 610 | 900 |

!!OUT OF STOCK ON THE WEBSITE!!

CALL NOW FOR FACTORY STOCK LEVELS

We have a huge range of stock in the UK that can be dispatched at short notice…. so if you need something fast please give us a call or drop us an email, then we can check factory stock levels and get back to you.